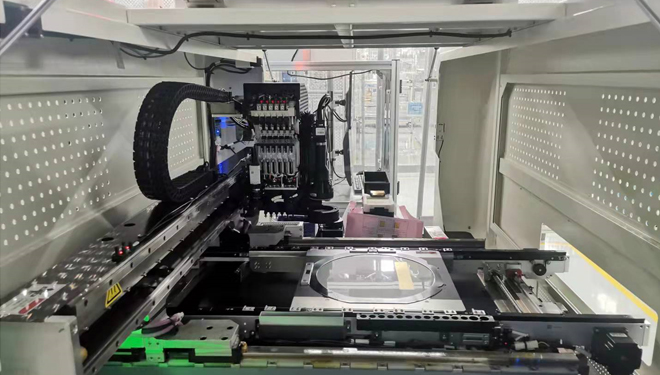

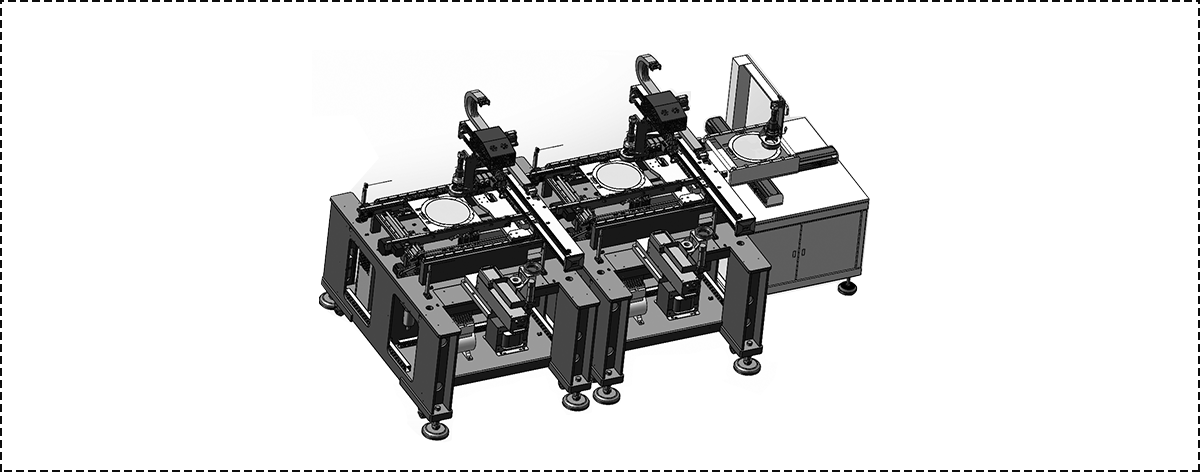

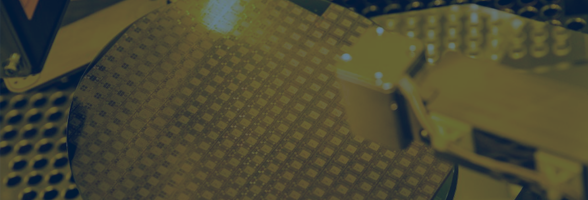

The solution based on AI computer vision can inspect wafer defects and dimensions, and mounting good products onto PVC disk according to certain angle, position, pitch and direction, and outputting eMap file containing position, angle and other information for downstream manufacturers' production use. The wafer is a copper wafer of size 0.9*0.81mm, and it needs to inspect both front and back sides. Because of the small size of wafer and high CT requirement, so it is completed by using placement machine with optical inspection.