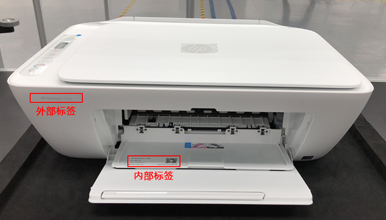

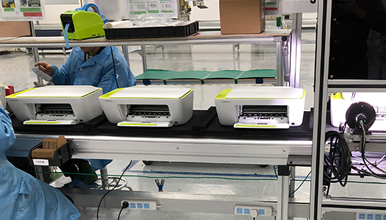

Existing production lines mostly use manual inspection of label content and defect detection, there are inefficiency and poor reliability, high defective rate, production

labour and after-sales costs, brand image damage and other issues.

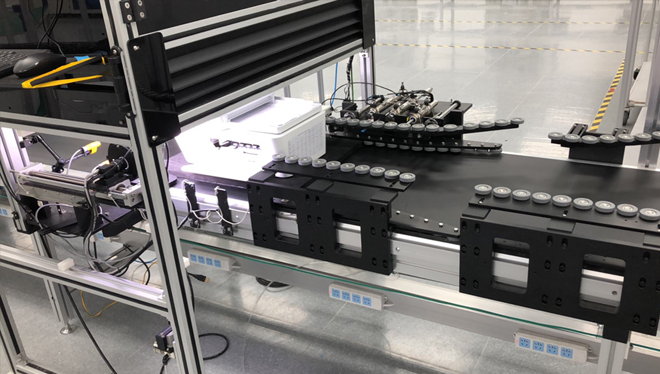

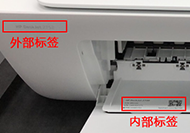

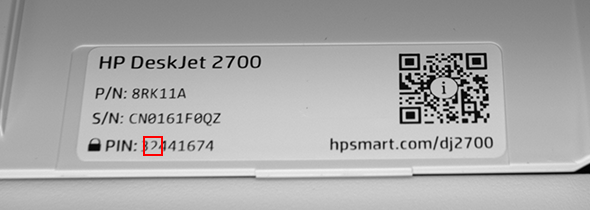

Dihuge "AI-based label dynamic inspection system", based on AI vision of the deep neural network algorithm model as the core, combined with the appearance of the

inspection, barcode reading, label content recognition and defect detection modules, a complete set of multi-functional intelligent integrated system, can quickly

complete the customised development, localised deployment, and effectively solve the above problems. Solve the above problems.