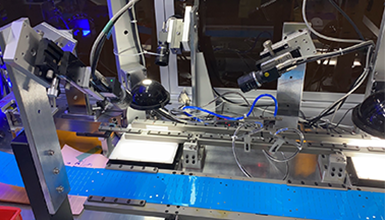

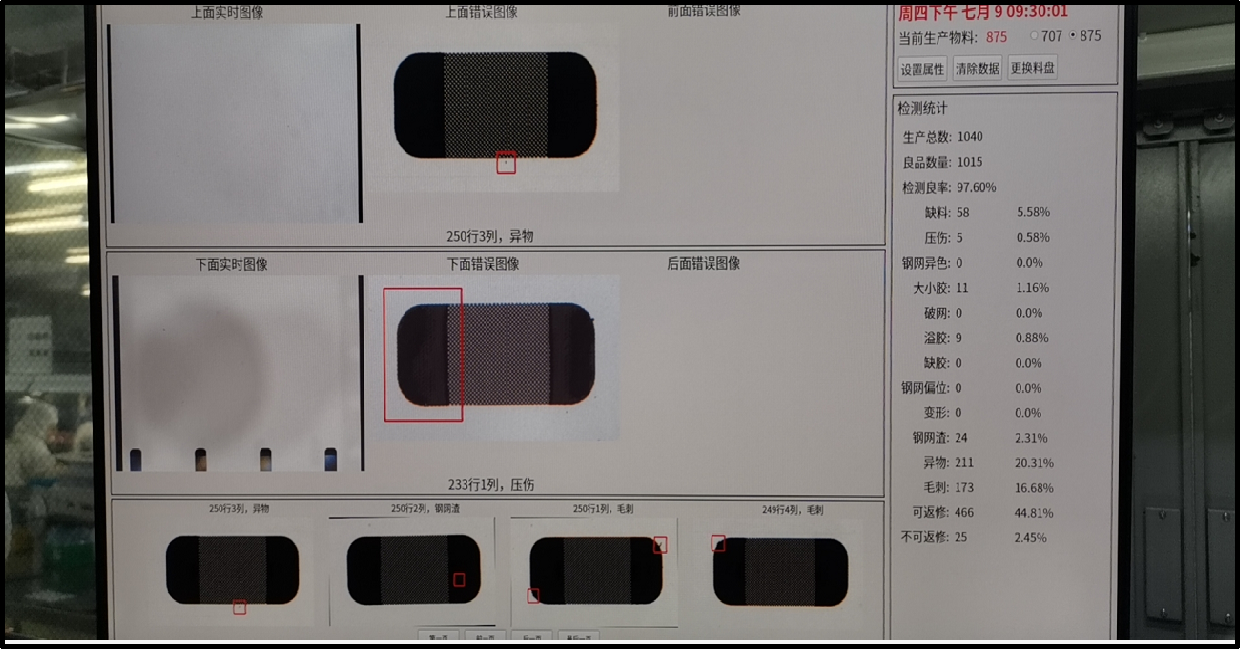

The 2D/3D mesh defect inspection solution based on AI computer vision adopts TimesAI deep learning development platform independently developed by Dihuge, integrating CV+AI+Automation, to achieve online real-time appearance defects detection, defective product removal, yield management, and other aspects of 3C mesh precision small parts.

The system effectively solves three major difficulties in the field: 1. The difference in the occurrence probability of different types of defects is large, and imbalance of defect samples. 2. Defects are small target defects. 3. Defect types have different semantic levels.

Currently, the system covers dozens of defect types, such as: steel mesh hull deformation, bending deformation, foreign object, clamping waste, burr, hull mesh breaking, wire mesh separation, steel mesh offset position, steel mesh deformation, steel mesh slag, wavy edges, large and small edges, liner offset position, liner more product, leaky white, peeling glue, lack of glue, overflow glue, glue offset position, and so on.