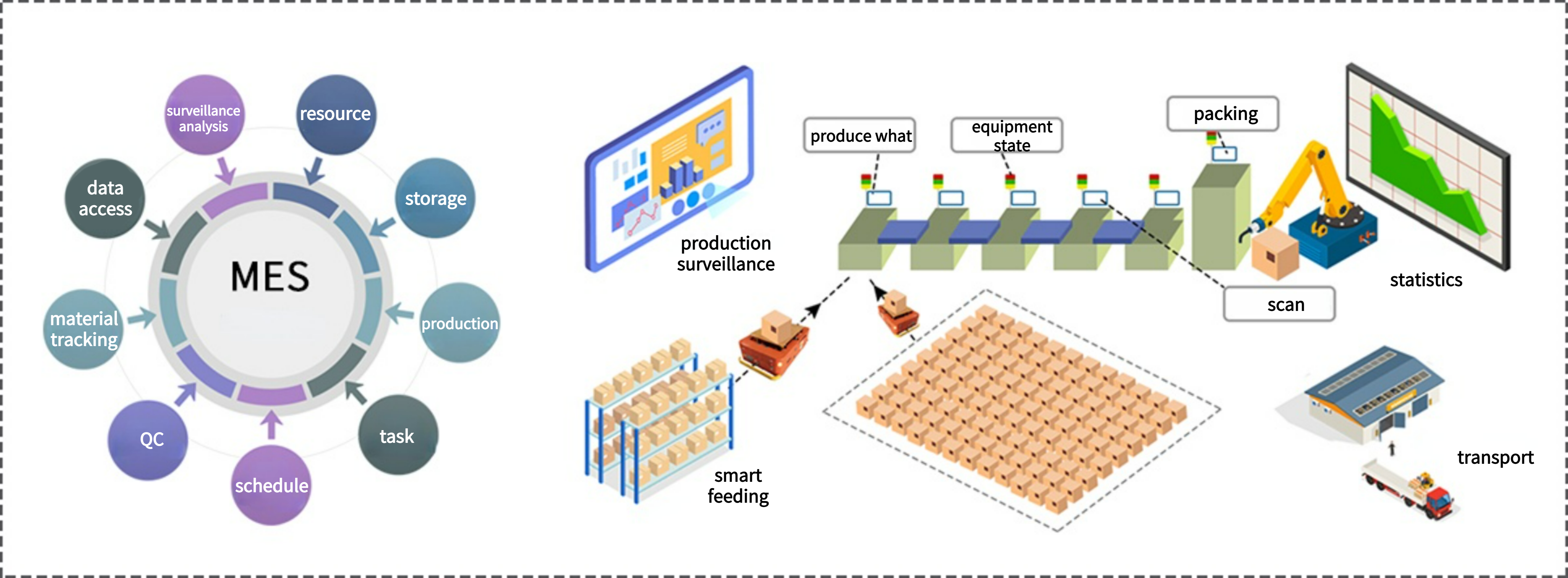

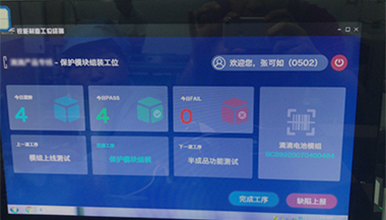

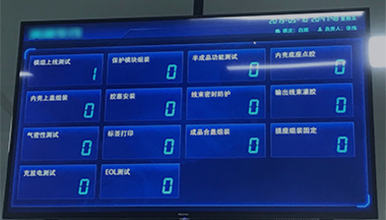

Manufacturing Process Execution Management Solution, or MES for short, mainly realises manufacturing data management, planning and scheduling management, production dispatching management, quality management, equipment management and other functions. This can help companies collect data from the production process, optimise the manufacturing process across the shop floor, and provide efficient allocation of production resources, reduce waste, and improve the core competitiveness of the enterprise.